Aiming at the problem of coated sand casting

1. Control the supply quality of coated sand

A key step in making high-quality castings is to ensure the quality of coated sand. When purchasing coated sand, the store must provide a product quality inspection report. Before making a large-scale purchase, sample selection and inspection of some coated sand must be carried out, and the quality must be fully checked.

2. Determine the strength and gas generation of coated sand

The addition amount of phenolic resin affects the strength of coated sand. The amount of phenolic resin added is large, the strength is high, the gas evolution increases, and the collapsibility decreases. Therefore, the amount of phenolic resin must be accurately calculated to ensure the strength of the coated sand, reduce the amount of gas, and improve the collapsibility. In order to fully ensure the surface quality of the sand core and prevent deformation and cracking during the pouring process, the foundry must continuously explore the amount of phenolic resin added during the forging process to meet the requirements of improving collapsibility and reducing gas evolution. Only in this way can the castings produced by the coated sand casting process have excellent characteristics and quality.

3. Storage period of coated sand core

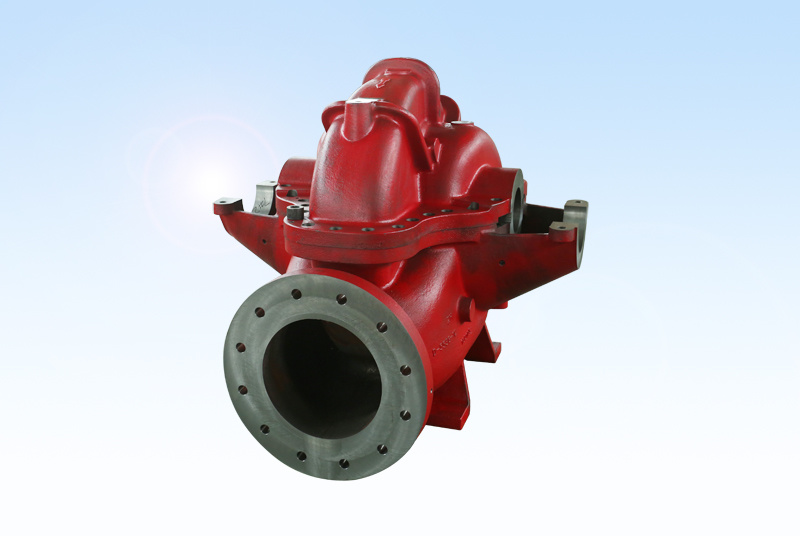

Most sand cores will be damp during storage, especially in the south where the air humidity is relatively high. Therefore, the storage period of the sand core must strictly implement the line pipe requirements. At the same time, the foundry should also reasonably control the temperature and humidity of the rolling mill through mechanization and industrialization to ensure that the coated sand core of the coated sand casting pump body is dry.

4. Fracture and deformation of sand core

In the forging process, some foundry manufacturers have selected high-quality coated sand raw materials, but under specific core-making conditions, the hinge coated sand casting sand core may crack and deform, which always makes foundry manufacturers very confused. In fact, this may be caused by a variety of reasons, so it is necessary to conduct a specific analysis of different situations.

Related News

2024/09/11

What is the function of the valve body?

The valve body is the main component of the valve body, and there are different mechanical manufacturing methods according to the pressure level.

View Details