Introduction of casting performance and application and coated sand process

Performance:

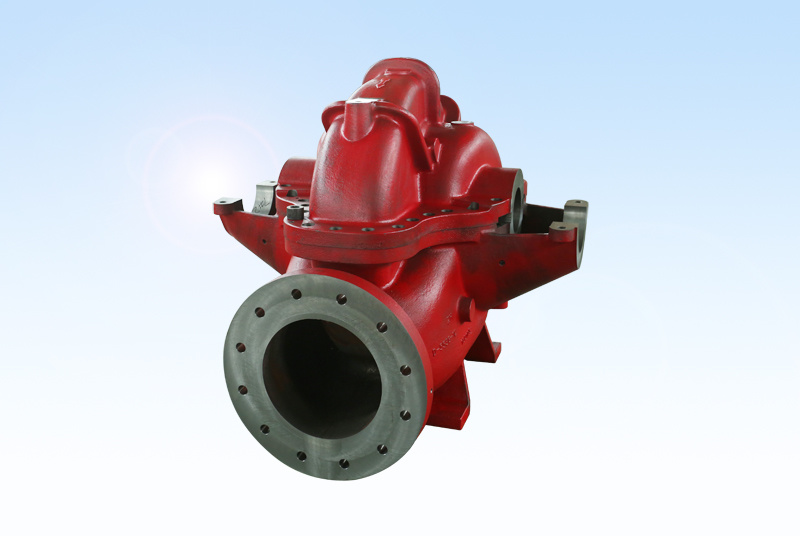

Castings have excellent mechanical and physical properties, it can have a variety of different strength, hardness, toughness with the comprehensive performance, but also can have one or more properties, such as, and low temperature, and so on. The weight and size range of castings are very wide, the light weight is only a few grams, the weight can reach 400 tons, the wall thickness is only 0.5mm, the thickness can be more than 1 meter, the length can be from a few millimeters to more than ten meters, which can meet the requirements of different industrial sectors.

Use:

The use of castings is very extensive, and it has been applied to hardware and the entire mechanical and electronic industry, and its use is becoming a growing trend. Specifically used in construction, hardware, equipment, construction machinery and other large machinery, machine tools, ships, aerospace, automobiles, locomotives, electronics, computers, electrical appliances, lamps and other industries, many of which are exposed to ordinary people all day long, but do not understand metal objects.

coated sand process:

The sand surface of the coated sand is covered with a layer of solid resin film before molding or core sand. There are two coating processes: cold method and hot method: cold method dissolves resin with ethanol, and adds urotropine in the sand mixing process to coat the two on the surface of sand particles, and ethanol volatilizes to obtain coated sand; Heat method preheats sand to temperature, adds resin to melt it, stirs resin to coat the surface of sand particles, adds urotropine aqueous solution and lubricant, cools, crushes and sieves to obtain coated sand. Used for steel castings and iron castings.

Main features

1, vibration sand cleaning, low gas, low expansion; 2, good lax, casting surface finish high; 3, shell can not afford layer, good thermal stability, good thermal conductivity, good fluidity; 4,. The shell type cannot afford to be layered,. Good thermal stability,. The surface of the casting is smooth and has good thermal conductivity; 5,,, low expansion,. Good demoulding and good sand resistance; 6. The shell layer is uniform and not shelled and cured.

Related News

2024/09/11

What is the function of the valve body?

The valve body is the main component of the valve body, and there are different mechanical manufacturing methods according to the pressure level.

View Details