Knowledge of machine tool castings

Machine tool castings mainly include mainframe castings, vanishable mold machine castings, resin sand machine castings, bed castings. As large castings, machine tool castings need to be heat treated to improve their performance and improve the internal quality of cast iron plates. Metal heat treatment is one of the important processes in mechanical manufacturing. Heat treatment usually changes the internal microstructure of the workpiece or changes the chemical composition of the workpiece surface without changing the shape and overall chemical composition of the workpiece, thereby improving or improving the performance of the workpiece. Its characteristic is to improve the internal quality of machine tool castings.

Brief Introduction of 1. Machine Tool Castings

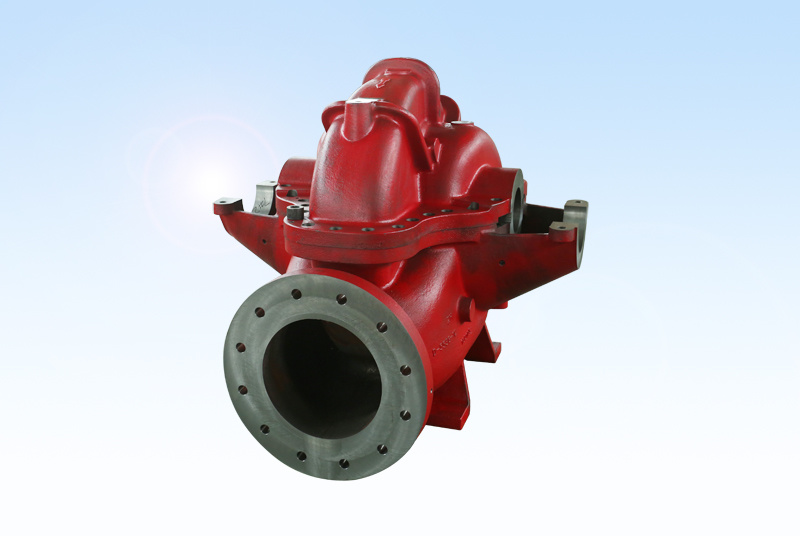

The machine tool castings are produced by a complete resin sand production line, all of which are resin sand castings. The machine castings are made of high-strength cast iron, with strong resistance, high dimensional accuracy, uniformity, no warping, no flash, and no defects. The surface is smooth and close to precision casting, and the internal structure is stable. The entire production process of machine tool castings does not produce pollution, and the three-level environmental protection can eliminate or reduce casting defects such as bubbles and pores.

The main use of 2. machine tool castings

Machine tool castings have the advantages of high dimensional accuracy, good rigidity, less machining allowance and excellent surface quality. Easy to operate, shorten the production cycle, improve production efficiency. Widely used in instrumentation, standard parts, bearing industry, electronics, light industry, auto parts and other industries. Especially suitable for non-ferrous metals. Machine tool castings have good wear resistance and consumption. Low melting point, good fluidity, small shrinkage. Machine tool casting features: good wear resistance. The graphite of cast iron is good for lubrication and oil storage, so it has good wear resistance. In addition, due to the presence of graphite, its consumption is better than steel.

Casting method for 3. machine tool castings

First choose sand casting machine castings, because sand casting is cheaper than other casting methods, the production process is less mechanized, and the production cycle is not long, so the quality can be guaranteed. If the wet method does not meet the requirements, the plasticine sand flow dry method, dry method or other methods can be considered.

Overall heat treatment of 4. machine tool castings

The overall heat treatment is a metal heat treatment process that heats the machine tool castings as a whole and then cools them at an appropriate speed to change the overall mechanical properties. The overall heat treatment of steel generally has four basic processes: annealing, purification, tempering and tempering. The general annealing process of annealing heat treatment method for machine tool castings includes recrystallization annealing, stress relief annealing, spherical annealing and complete annealing.

Related News

2024/09/11

What is the function of the valve body?

The valve body is the main component of the valve body, and there are different mechanical manufacturing methods according to the pressure level.

View Details