Installation requirements of coated sand casting safety valve

Coated sand: boiler safety valve installation requirements shall meet the following requirements:

(l) Boilers with rated evaporation exceeding 0.5 t/h and rated evaporation less than or equal to 0 shall be equipped with at least two safety valves. Boilers with at least one safety valve installed at 5 t/h. The safety valve must be installed at the outlet of the steam heating surface, and the outlet of the rational economizer can be used.

(2) The safety valve should be installed vertically in the larger position of the pot merchant and the drum. Outlet pipes and gate valves shall not be provided between safety valves, furnace walls or drums.

(3) The lever safety valve relies on the equipment to avoid the independent movement of the heavy hammer and limit the cheating behavior of the lever. The spring safety valve relies on the equipment to raise the handle and avoid turning the adjusting screw at will.

(4) Boiler mm with rated steam pressure less than or equal to 3.82MPa safety valve throat diameter not less than 25: Boiler mm with rated steam pressure exceeding 3.82MPa safety valve throat diameter not less than 20.

(5) The cross-sectional area of the boiler safety valve and hose shall not be less than the inlet cross-sectional area of the safety valve. The cross-sectional area of the channel of the pipe clamp is not connected to the short pipe installed with several safety valves, and the cross-sectional area of the channel of the pipe clamp shall not be less than 1.25 times the exhaust area of all the safety valves.

(6) The safety valve should generally be installed with an exhaust pipe. The exhaust pipe of the coated sand casting pump body should directly reach the safety site and have sufficient cross-sectional area to ensure smooth exhaust. A model shall be installed at the bottom of the safety valve exhaust pipe, and the drain pipe received in a safe position shall not be installed on the exhaust pipe and the drain pipe.

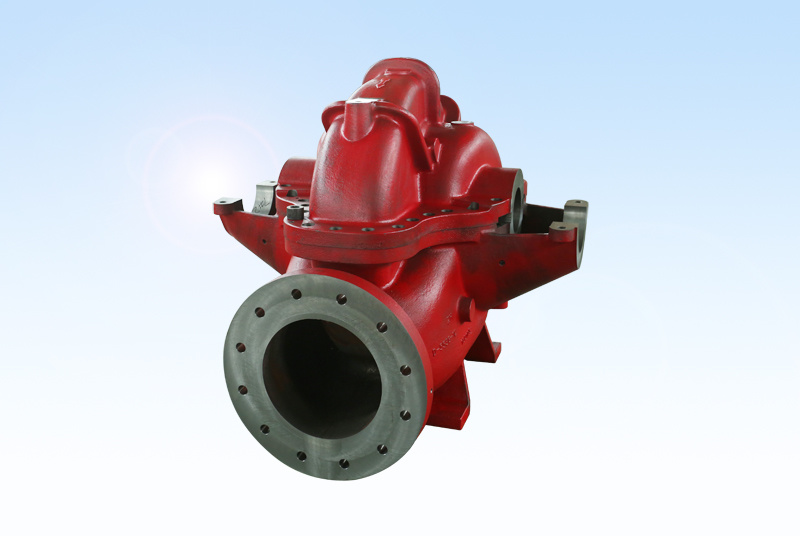

A method for coating sand casting process, according to the core shooting machine, the coating sand raw material is injected into the casting mold with an overall temperature of 350 ℃ ~ 450 ℃, the openings on both sides of the coating sand casting water pump valve molding core are combined with the surrounding outer wall, and the prefabricated casting end cover glue is fixed in the openings on both sides of the casting mold. The film sand casting and curing time is 30 seconds to 50 seconds in the above mold. The invention has the advantages of short production cycle, high efficiency, zero pollution, small sewage discharge, environmental protection and the like.

Related News

2024/09/11

What is the function of the valve body?

The valve body is the main component of the valve body, and there are different mechanical manufacturing methods according to the pressure level.

View Details